Views: 3 Author: Site Editor Publish Time: 2024-06-12 Origin: Site

In recent years, with the decreasing availability of petroleum resources and rapid industrial development, the demand for engine oil has increased significantly. However, the issue of recycling, treating, and utilizing waste engine oil cannot be ignored. Due to its high content of harmful substances and resistance to degradation, improper disposal of waste engine oil can lead to environmental pollution, posing significant threats to human and biological habitats.

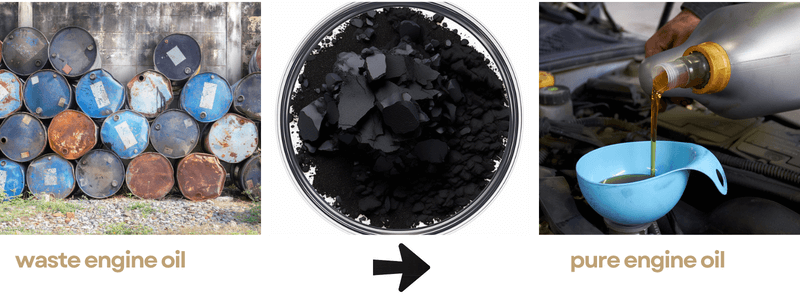

Activated carbon, as an efficient adsorption material, has found widespread application in the decolorization and regeneration of waste engine oil. This article will focus on introducing methods for treating waste engine oil and the application of activated carbon in this process.

Commonly used engine oil is mineral-based, derived from processed petroleum.

During its use in engines and gearboxes, engine oil absorbs various harmful pollutants such as lead, cadmium, chromium, arsenic, dioxins, benzene, etc. The operation of the engine may lead to contamination and impact on the lubrication system, ultimately affecting engine performance. Improper disposal of used engine oil may result in groundwater pollution, endanger human health, and contribute to environmental degradation.

Waste engine oil poses serious hazards to nature and humanity. The following section will discuss some common methods for the correct disposal of waste engine oil.

The proper treatment of waste engine oil is a crucial environmental task as its mishandling can lead to severe harm to both the environment and human health. Common methods for decolorization and regeneration of waste engine oil include precipitation, distillation, acid washing, alkali washing, adsorption, and filtration.

Precipitation: Separates large particles and impurities in waste engine oil through the precipitation method. The settling time is determined by the oil quality and temperature; higher temperatures result in shorter settling times.

Distillation: Removes moisture from engine oil thoroughly and separates low-boiling-point substances such as gasoline and diesel, maintaining the desired viscosity of regenerated oil. Gasoline is separated at temperatures up to 180 degrees, and diesel is separated between 180-360 degrees.

Acid Washing: Utilizes concentrated sulfuric acid to separate and precipitate most impurities in waste engine oil.

Alkali Washing: Primarily used to remove organic acids from waste engine oil and neutralize the sulfuric acid residue from acid washing.

Water Washing: Removes water-soluble impurities such as acids and alkalis from waste engine oil.

Adsorption: Involves heating the oil to a certain temperature, adding activated carbon to the waste engine oil, stirring, and then allowing it to stand.

Filtration: The oil, after adsorption by activated carbon, is vacuum-filtered to obtain the finished product, completing the regeneration process.

Activated carbon plays a crucial role in the treatment of waste engine oil, effectively adsorbing pollutants, improving oil quality, reducing replacement frequency, and saving costs.

Adsorption of Pollutants: Activated carbon removes carbon deposits, ash, metals, and other solid pollutants accumulated in waste engine oil, thereby increasing the flash point and ignition point of engine oil.

Improvement of Oil Quality: Activated carbon adsorbs and filters impurities, enhancing the quality of engine oil. The filtered oil exhibits improved lubrication properties.

Cost Savings: Regenerated engine oil treated with activated carbon can be reused, reducing waste and environmental impact.

Environmental Sustainability: Using activated carbon to remove pollutants from petroleum prevents their release into the environment, promoting sustainable resource management.

For waste engine oil decolorization and recovery, our company offers a wood based powdered activated carbon. This activated carbon stands out for its excellent decolorization effect, effectively treating carbon deposits, ash, and other solid pollutants. For customers with waste engine oil treatment needs, this environmentally friendly choice may be the sustainable solution you are seeking.

If you are looking for sustainable solutions related to waste engine oil, we invite you to contact us to embark on an eco-friendly journey.

Commonly used activated carbon decontamination techniques in water treatment industry

Activated carbon water purification effectively removes contaminants, ensuring safe drinking water

Investigate thoroughly the benefits and drawbacks associated with various forms of coal-derived act

Principle of ozone-biological activated carbon (O3-BAC) technology and its role in water treatment